Characteristic of Cut Knurlilng Tool

Turning external diameter cut knurling tool can adjust the cutting angle, can protect the accuracy of the machine tool, for small machine tools, rigid requirements are low.

Applicable types of machine tools: CNC lathe, automatic lathe, multi-axis lathe, Swiss automatic lathe, Lathe-milling machine tools.

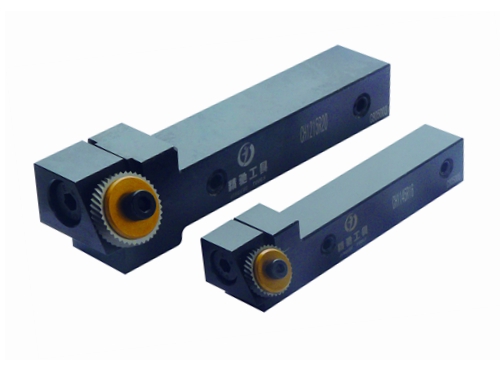

Single Wheel Cut Knurling Tool

The Tool can process straight lines and left or right cross grain,the cutter head and handle of cutter are provided with fine turning function.

Knurling Type

Knuling Type

Cut Knuling Wheel

Feed Type

RAA

BR30°

F←

RBR30°

AA

F←

RAA

BL30°

F←

RBL30°

AA

F←

Imported Cut Wheel

AA

BL15°

BR15°

BL30°

BR30°

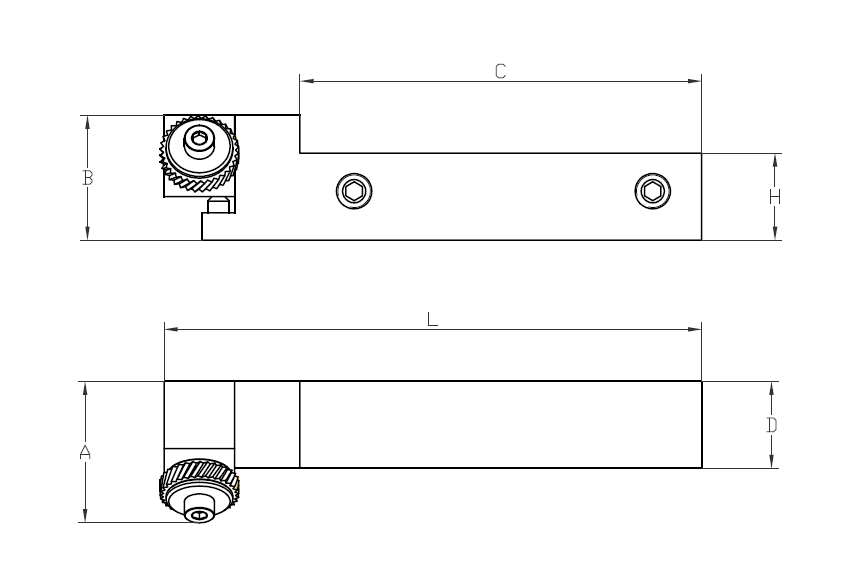

Product Data

| Model | Direction | Processing Range | Wheel Size | Tool Shank Size | Spare Part | ||||||

| A | B | C | D | H | L | ||||||

| CH1145R14 |

R+L |

Φ3-50 | Φ14.5×3×5 | 26 | 23 | 74 | 16 | 14 | 99 | EAT14.53 |

|

| CH1145R16 | 16 | ||||||||||

| CH1215R20 | Φ5-250 | Φ21.5×5×8 | 39 | 36 | 114 | 25 | 20 | 149 | EAT21.55 | ||

| CH1215R25 | 25 | ||||||||||

Cut Knurling Tool Use Method

1.Install tool into tool holder and adjust tool center height to ensure center position of workpiece.

2.Adjust the wheel to the outer diameter of the workpiece and adjust the width of the two wheels to close the workpiece.

3.Start to work,fast cut 1/2 of the teeth pitch and width is about 1/3 of wheel

4.Start Z axial feed when the knuling pattern is finished.

5.If the tooth type is faulty, adjust the axial adjustment of the cutter holder.

6.Use larger cutting fluid or lubricant to remove the iron scraps